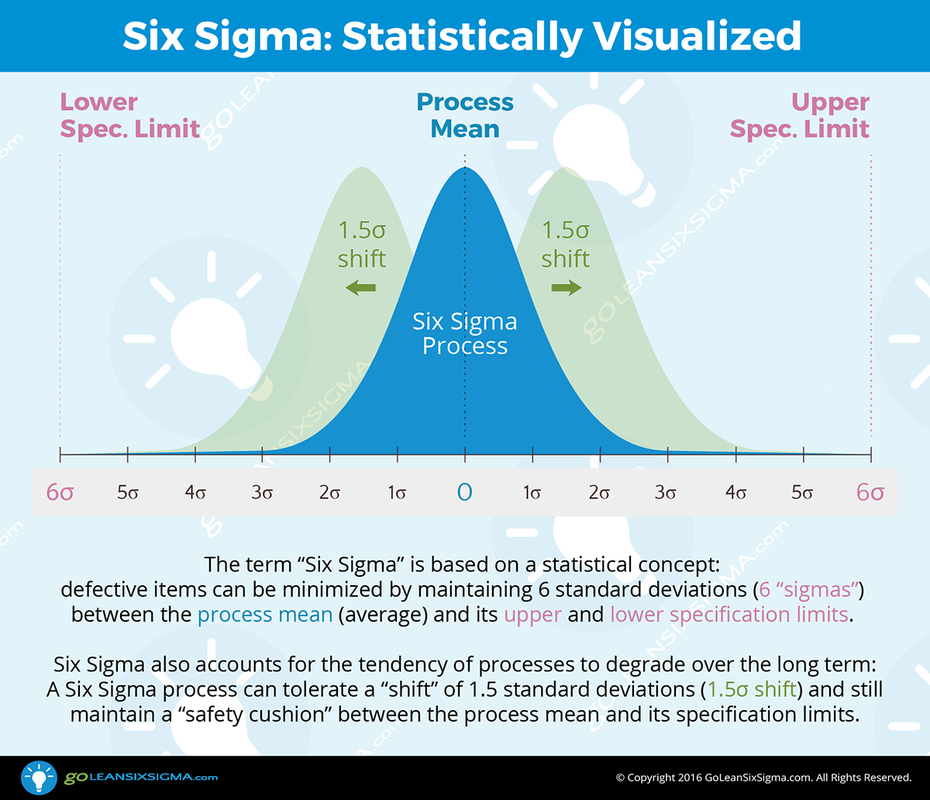

This will be discussed further below along with what the Six Sigma program represents, what mathematically this means, and finally what a Gaussian distribution is. 3.4 failures per one million opportunities represents 4.5 standard deviations (sigma) away from the median value, either up or down, under a bell curve. To reiterate, the term "Six Sigma" comes from the standard deviation and the Gaussian distribution. This leaves very slight room for error on a process and leads to a very high level of quality in the products. We will be using the shifted mean scenario for the rest of this article when referring to opportunity goals. The 4.5 vs 6 standard deviations is the same goal, but the 4.5 represents data variation in the long run, which is used in most processes. Using this idea, the goal for the Six Sigma program is to have fewer than 3.4 failures per one million opportunities when the data is evaluated to include the shifted mean from process variability (6 standard deviations - 1.5 standard deviations = 4.5 standard deviations). Most companies are looking on a long term scale, because they would rather have a good/safe product in the long run/for a long time rather than for a short amount of time. This shift of the mean is by 1.5 standard deviations. The short term data variability which makes up long term variability tends to cause the mean to shift. Both of these studies are evaluated on a Z-scale. Studies run to obtain this goal are short term capability studies, which include common cause or random variation, such as operator control, and long term studies, which include random and special types of variation. The Six Sigma program strives to achieve six standard deviations between the mean and the closest specification limit on a short term study. Six Sigma is also used in developing new processes.

DFSS (Design for six sigma) starts earlier, to develop or redesign the process itself, so fewer wrinkles show up in the first place, thus systematically preventing downstream errors. The Six Sigma program is in place to eliminate any abnormalities, failures, or defects that occur within a given process. Some of these other large companies include GE, Honeywell, and Bank of America. It was first put into implementation at Motorola, but is now in use by most large corporations. Six Sigma is a relatively new program, and was only started in 1986. The quality program that is currently in vogue and being widely used and recognized by industry is the Six Sigma program. We would be happy to help you get started on your transformation journey.\)Įvery generation of business strives for a new level of quality. If you’re interested in learning more about Six Sigma and how it could benefit your business, get in touch with us. It can be applied in any industry, and the benefits are clear. Sigma is a business strategy used for decades to improve quality and productivity. Once these things are in place, you can begin implementing Six Sigma within your company. There are two main approaches: DMAIC (Define, Measure, Analyze, Improve, Control) and DMADV (Define, Measure, Analyze, Design, Verify). Finally, you need to decide what type of Six Sigma approach you want to use. These employees will receive training in Six Sigma methods and tools and help implement Six Sigma projects within your company. Once you have a champion, you need to select a Six Sigma Green Belts team. This is someone responsible for leading and overseeing the Six Sigma initiative within your company. First, you need to identify a Six Sigma Champion. If your business is interested in Six Sigma, there are a few things you need to do to get started.

0 kommentar(er)

0 kommentar(er)